The restoration of the historic Iron Bridge

The restoration of the historic Iron Bridge, a symbol of the Industrial Revolution, is about to finish.

The project that was constructed over the River Severn at Coalbrookdale, England, in 1779 is located in an area full of minerals, coal and iron ore.

Iron Bridge is one of the most influential constructions in modern civil engineering and is considered the ancestor of railways and skyscrapers. It was the world's first single-span arch bridge to be made of cast iron.

After its erection, it was observed that its abutments were being pushed together due to ground movement. In 1801, the board of directors considered holding the abutments apart using a timber support bar but the idea was rejected. However, the issue was addressed over 150 years later in a period when the bridge came very close to collapse as the abutments were displaced by about 60 cm. Therefore, a concrete support bar was constructed to hold them apart.

Recent investigation showed that severe cracking poses a threat to the construction. Cracking was caused by stresses in the ironwork dating from the original construction but it has been amplified since the addition of the aforementioned concrete support bar that caused the structure to be under compression and due to a powerful earthquake that struck the region in the 19th century. Moreover, corrosion of the iron is also an issue that threatens the structure's stability.

After carrying out a detailed investigation, Consultant Ramboll created a finite element model to simulate the behavior of the structure. The results showed that the bridge's framework does not have to be reinforced but its elements have to be examined and replaced if needed. "We haven't had to strengthen the structure. The Iron Bridge was in vehicular use for a long time, so there is quite a high degree of redundancy, which means there is no problem with its load-bearing capability. What we're doing now is a case of really trying to make sure that, where elements are damaged or have failed, they won't fall off in the future, and we can retain them for as long as possible," Morton Partnership, the company that conducted the design of the works using Ramboll's report, stated.

One of the most challenging tasks that had to be tackled during the restoration was the replacement of over 250 corroded wedges in the deck. For each replacement, an individual plywood template was made before crafting a new cast-iron wedge. "It was quite an intensive job," Matt Greenhalgh, technical and estimating engineering director, commented.

Play the video below for more information about the restoration works of the bridge.

Sources: Theconstructionindex.co.uk, Ironbridge.org.uk

Media

- Project Iron Bridge

Want to read more like this story?

Types of bridges

Jun, 01, 2023 | EducationArch Bridge An arch bridge is a type of bridge that uses a curved, semi-circular structure, kno...

An engineering point of view for the Tacoma Narrows Bridge collapse

Apr, 04, 2023 | EducationIntroduction An iconic civil structure is a bridge. The desire for humans to go from place to...

Bridge railing collapse in Chattanooga, Tennessee

Apr, 22, 2019 | NewsA concrete beam from a bridge located in Chattanooga, Tennessee failed and collapsed injuring one pe...

The most famous bridges of the world

Aug, 26, 2015 | NewsThere are so many bridges in the world in different styles, like old stone bridges or steely, footbr...

Historic bridge collapses in Ohio: Footage recorded on camera

Jul, 17, 2019 | NewsOne of the longest covered bridges in Ohio, constructed more than 150 years ago, collapsed. The 3...

A bridge in Bhoranj collapsed hours after the shutters were removed

Mar, 31, 2023 | NewsA bridge, that was still being built, collapsed close to the village of Jahu in the Public Works De...

Bridge collapse in Taiwan: 5 people confirmed dead

Oct, 07, 2019 | NewsAn arch bridge located in eastern Taiwan suddenly collapsed sending an oil tanker truck onto fishing...

Florida pedestrian bridge collapses 5 days after its installation

Mar, 21, 2018 | NewsThe bridge, which was expected to open in January 2019, was being built using a method called a...

Bridge collapse near Hurley: OSHA investigation

Dec, 14, 2018 | NewsOn November 21, 2018, a bridge collapse near Hurley, Wisconsin, resulted in injuring 3 workers....

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

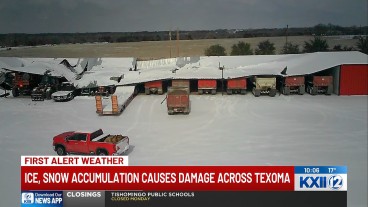

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran