New system to construct a bridge span in 3 days

A quick deployable bridge system was presented by the University of Maine Advanced Structures and Composites Center.

The system uses composite material girders and precast concrete deck panels in order to reduce time and benefit financially in a bridge construction. The girders are reinforced with a hybrid composite containing thermoset resin, glass fiber and carbon fiber. Expects claim that a highway bridge can be constructed in 72 hours. The system includes a unique shear connection that allows the precast panels to be connected onsite, explains Anthony Diba, a graduate research assistant working on the project.

The new project was officially tested in July 12, 2018. Researchers, UMaine staff, Maine Department of Transportation officials and investors among others, observed a bridge span being strength-tested using computer-controlled hydraulic equipment that simulates the heaviest highway truck loads. The aim of the test was to prove the design modeling predictions and to demonstrate that the bridge system can withstand the truck loading specified in the American Association of State Highway and Transportation Officials (AASHTO) Bridge Design Specifications.

The strength-test proved to be more than successful. Dr. Habib Dagher, executive director of the UMaine Advanced Structures and Composites Center, stated "The bridge test exceeded our expectations. The composite bridge withstood forces equivalent to more than 80 cars stacked on top of each other, and more than 5 times the HL 93 design load specified by AASHTO. The composite bridge girder exceeded twice the collapse strength of steel and concrete girders. Today was truly a remarkable engineering achievement made possible by research sponsored by the U.S. Army Corps of Engineers and the dedication and hard work of University researchers." Dagher also explained that the system benefits both from the properties of composite materials and precast concrete. The girders weight is about 1-2 tons when the length of the spans ranges from 40-80 meters. Their deployment is easy and can be achieved by common cranes.

The new system can be applied for highway bridges, pedestrian bridges and military applications. In addition to reducing construction time and logistics, the girders are designed to last 100 years while and the precast concrete deck can be easily removed and replaced.

Source: Compositesmanufacturing

Want to read more like this story?

New bridge building method : The "umbrella" method

Aug, 05, 2020 | NewsA new bridge construction method, which was introduced by structural engineers at the Vienna Univer...

OpenBridge Designer

Aug, 28, 2023 | Software

Types of bridges

Jun, 01, 2023 | EducationArch Bridge An arch bridge is a type of bridge that uses a curved, semi-circular structure, kno...

An engineering point of view for the Tacoma Narrows Bridge collapse

Apr, 04, 2023 | EducationIntroduction An iconic civil structure is a bridge. The desire for humans to go from place to...

Six Injured in Brent Spence Bridge Crash

Aug, 05, 2014 | NewsSix people were injured this weekend in Cincinnati, Ohio when a car fell off the southbound deck of...

The most famous bridges of the world

Aug, 26, 2015 | NewsThere are so many bridges in the world in different styles, like old stone bridges or steely, footbr...

Historic Oregon Bridge For Sale

Aug, 15, 2014 | NewsIf anyone is in the market for purchasing an old bridge here is your chance. Multnomah county i...

Bridge Design

Jan, 01, 2019 | EducationBridge design is the process that involves the conceptualization, the strategic planning, and the...

UPDATE: Tappan Zee Bridge Site Gets Own Concrete Plant

Jul, 23, 2014 | NewsWorkers began drilling piles for the Tappan Zee Bridge in March. Since then, equipment has slowly ac...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

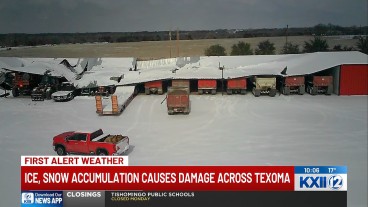

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran