Improving concrete's fire resistance with tire fibers

In a new study, researchers have developed a method to improve concrete's performance when subjected to fire using recycled fibers from tires.

The study was conducted by scientists from the University of Sheffield, United Kingdom, and was recently published in the journal Fire Technology. It was shown that when tire fibers are added in the concrete's mixture, the result is a decrease of its explosive spalling: The heat produced by the fire vaporizes water in the concrete. The ensuing pressure is initially released into the pores of the concrete. However, as the pressure continues to rise, pieces of concrete blast off and intense cracking occurs.

This issue is resolved when utilizing fibers as they tend to melt when exposed to high temperatures creating a channel network that enables steam to escape and thus, high pressures are not produced. Moreover, the influence of those fibers on the mechanical properties of concrete is minor. "Because the fibers are so small, they don't affect the strength or the stiffness of the concrete. Their only job is to melt when heat becomes intense. Concrete is a brittle material, so will break out relatively easily without having these fibers help reducing the pressure within the concrete," said lead author of the study, Dr. Shan-Shan Huang.

Another benefit of the fibers' usage is their ability to protect the steel reinforcements inside concrete structures. Steel bars are vulnerable to high temperatures. When they are exposed to extreme heat, their bearing capacity significantly deteriorates and a building is prone to collapse.

Currently, in some buildings, polypropylene (PP) is used to protect concrete in case of fire incidents. PP has the same effect as fibers. However, fibers can be produced directly from used tires while PP is manufactured from raw materials. "We've shown that these recycled fibers do an equivalent job to 'virgin' PP fibers which require lots of energy and resources to produce. Using waste materials in this way is less expensive, and better for the planet," Dr. Shan-Shan Huang commented.

The next phase of the team's research is to investigate the effect of different proportions of fibers in the concrete mix and to understand how each material responds to heat on the micro scale.

Source: Insights.globalspec.com

Want to read more like this story?

Fibers to help fire damage prevention in tunnels

Feb, 25, 2015 | NewsEngineers at the Technical University of Munich (TUM) have come up with a way to prevent concrete sp...

Concrete Structures

Jan, 01, 2019 | EducationConcrete structures are constructions that utilize concrete as the primary building material. Conc...

Strengthening and repairing concrete structures using paper-thin carbon fiber reinforced polymers

Apr, 07, 2021 | NewsA new method to strengthen and repair deficient bridges with paper-thin material has been recogni...

Concrete damage based on 4 crucial factors

Feb, 01, 2024 | NewsConcrete often sustains damage due to various factors, either environmental or mechanical. In the f...

Fire-damaged concrete structures: how do we know when to fix or rebuild a concrete structure after a fire?

Nov, 15, 2021 | NewsGenerally, when concrete is exposed to intense fire, materials in the concrete can decompose, and c...

Zero-cement concrete will reduce the environmental impact in construction industry

Aug, 08, 2024 | NewsDue to the climate crisis and the high CO2 emissions of concrete, engineers and scientists are seek...

The world’s first carbon concrete building constructed by researchers in Germany

Nov, 10, 2022 | NewsThe first building made of carbon-reinforced concrete was inaugurated in September after two and a...

Concrete that traps CO2 emissions for good

Jul, 16, 2018 | NewsA new method to produce concrete that traps harmful CO2 emissions and increases the compression stre...

ADINA 2025 New Release!

May, 13, 2025 | NewsBentley Systems announced a new major release of ADINA. For a complete list of changes see ADINA...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

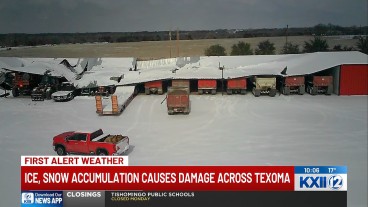

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran