Carbon-nanotube Reinforced Composite Materials and Structural Health Monitoring

By reinforcing composite parts with carbon nanotubes (CNTs), researchers from Rey Juan Carlos University in Madrid structural health monitoring can be achieved.

Carbon nanotubes provide electrical conductivity in the reinforced materials that they are applied to. In that way, a specified point with structural damage can be located by identifying the weakest electrical connection.

Initially, the researchers 3D printed, via DLP 3D printing technology, a set of six composite samples with CNT composition varying from 0.03% to 0.15% by weight. Then they tried to evaluate the impact of the carbon nanotubes on the electrical conductivity, something that could allow the creation of self-sensing composite parts. Nanotubes create a UV shielding effect, which leads to inadequate curing, therefore the specimens with higher composition of carbon nanotubes needed to be UV exposed for longer time. The researchers explained: “Their addition in low contents into an insulator resin allows the formation of electrical percolating networks inside the material, leading to an increase in electrical conductivity of the material of several orders of magnitude.”

Subsequently, tensile and three-point bending tests were conducted on each printed sample. During all tests, currents running though the composite parts were recorded. Copper wires with silver conductive paste, for the abatement of inter-material resistance at the connections, were used for the electrical connections.

Experimental formation of test specimens (Credits: RJCU)

Based on the experiments, it was concluded that electrical resistance is strongly correlated to applied strain and that the sensitivity increased as CNT content decreased. The last remark is explained because of the higher interparticle distance, which allows easier electrical charge transport.

Micrographs showing CNTs (0.1 wt % CNT specimen) distribution at (a) low magnifications and (b) high magnifications. (Credits: RJCU)

The results of this study make the research team believe that DLP-fabricated CNT reinforced composites could monitor precisely their structural damage. The study was recently published in Polymers.

Sources: Mechanical and Strain-Sensing Capabilities of Carbon Nanotube Reinforced Composites by Digital Light Processing 3D Printing Technology, 3dprintingindustry

Want to read more like this story?

Using carbon nanotubes for structural health assessment

Jul, 18, 2016 | NewsIf engineers can better understand the impact of hurricanes and earthquakes on structures, they coul...

Composite structures

Sep, 07, 2023 | EducationComposite structures refer to constructions that are composed of two or more distinct materials co...

New revolutionary cement composite created by University of Virginia: it promises greater durability in the field of 3D printing

Oct, 29, 2024 | NewsTo contribute to the global effort in the construction field to reduce carbon emissions, the resear...

New system to construct a bridge span in 3 days

Aug, 01, 2018 | NewsA quick deployable bridge system was presented by the University of Maine Advanced Structures and Co...

The world’s first carbon concrete building constructed by researchers in Germany

Nov, 10, 2022 | NewsThe first building made of carbon-reinforced concrete was inaugurated in September after two and a...

Composite Beam Designer

Aug, 28, 2023 | Software

10 state-of-the-art sustainable materials that will alter construction industry

Jun, 10, 2024 | NewsIn 2024, sustainable materials become state-of-the-art in construction since the construction indus...

Researchers use photos and new AI tool to calculate stress and strain fields of materials

Apr, 28, 2021 | NewsResearchers at Massachusetts Institute of Technology have developed a method to determine stres...

Bio-inspired composite cement: a new material to increase durability using natural principles

Jun, 28, 2024 | NewsPrinceton’s university engineers developed a new composite cement inspired by oyster and abalone sh...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

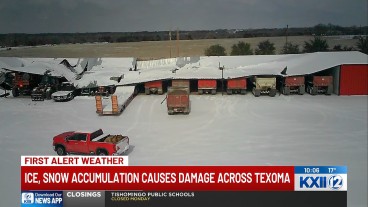

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran