Ohio’s first 3D-printed building is about to be constructed in Linden

The first 3D-printed building is about to be constructed on 26th Avenue in Linden, Columbus, Ohio by the contractor Mayo Makinde. The constructor is planning to build an 850-square-foot two-bedroom apartment. Makinde, the owner of Makinde Enterprises with the aid of a large 3D-printer had already built 8 feet of the walls, while he is anticipating completing the rest of the building within a day.

Furthermore, he suggests after the completion of the 3D-printed walls, he might need another 7 days to complete the plumbing, roofing, windows, and doors. He referred to the cost of the project and explained that the initial cost of the 3D printer was $1 million. However, the cost of the apartment is expected to be approximately $30,000. This highlights that the significantly reduced construction time is a revolution in the construction field and cost effective.

The construction process involves a 3D printer with a nozzle that dispenses concrete from a tall, mobile metal frame moving along tracks. The printer deposits successive thin layers of concrete, building up double-layered walls by stacking each layer precisely on top of the previous one. Therefore, the walls created during this process have a unique form and appearance, architecturally speaking.

It should be noted that the Ohio State’s CDME is hosting one of the largest 3D printing programs in the U.S. However, they are mainly focusing on printing with metals and polymers. The university’s spokesman stated that they have already used a large-scale concrete printer, comparable to the one that it is using now in Linden, to create large concrete molds. He added also that as of present they have rented this printer to Somerset Community College in Kentucky to facilitate their effort to build low-income homes in Appalachia. Last, as part of the program they are employing about 150 undergraduate students to prepare and educate them to work on a field upon graduation.

In all, the Columbus Deputy Director of Building noted that while the project showed potential, the city encountered challenges during the approval process. These setbacks arose from the need to adjust the house's positioning on the property to accommodate the large size of the 3D printer.

Sources: wosu.org, spectrumnews1.com, yahoo.com

Media

- First completed 3D-Printed home in Ohio, is this the future?

Want to read more like this story?

The world’s most exceptional 3D printed homes

Apr, 10, 2024 | News3D printing technology is a revolution at the construction sector, enabling builders to fabricate h...

1st 3D Printed Office Building

Jul, 01, 2015 | NewsThe United Arab Emirates announced that it will proceed with the creation of the first building to b...

Dubai plans to build the world's first 3D-printed mosque

May, 03, 2023 | NewsDubai aspires to build the world's first 3D-printed mosque, that will cover an area of 2,000 square...

World’s largest 3D printed building in Florida completed

Jun, 20, 2023 | NewsPrinted Farms, renowned for constructing Florida's initial authorized 3D printed house in Tallahass...

Printout homes using new techniques: the rise of 3D-printed houses

Aug, 18, 2021 | NewsPalari Homes and Mighty Buildings company is using a new technique to build houses within 24 hours....

Canada: The first three-story concrete building was constructed with the aid of 3D printing

Mar, 31, 2024 | NewsA three-story 3D-printed building, spanning an area of 420m2 and rising to 12.5m from its foundatio...

A 3d-printed house to withstand strong earthquakes was built in 26 hours

Oct, 25, 2023 | NewsA team in Guatemala used 3D printing technology to construct an earthquake-proof house within a rem...

New solution promises 90% cost reduction in concrete 3D printing materials

Dec, 22, 2021 | NewsConcrete 3D printing of building shells has grown considerably in the last few years, with more and...

Japan: The first railway 3D-printed building constructed within 2 hours

Jul, 22, 2025 | NewsOn Tuesday, July 22, the first 3D-printed train station building was constructed at Hatsushima Stat...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

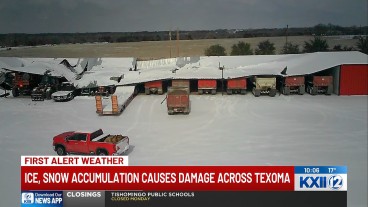

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran