The world’s most exceptional 3D printed homes

3D printing technology is a revolution at the construction sector, enabling builders to fabricate homes using 3D printing techniques in approximately 24 hours. This method employs large-scale 3D printers to deposit layers of specially formulated materials, primarily concrete or polymers, to construct components for housing construction, capable of being erected on-site or off-site within a few hours. This technique results in significant cost reductions. The printers follow predetermined paths, depositing each layer of material while outlining and extruding material until the construction process is completed.

The following lines present seven of the world's most exceptional 3D printed homes.

Curve Appeal was constructed by Wimberly, Allison, Tong & Goo (WATG) and is presented as the initial freeform 3D printed luxury residence in the world. The dawning of this project traces back to 2016 when architects in Chicago introduced a blueprint for a 3D printed dwelling crafted from plastic, carbon-fiber panels, and glass walls.

The Eindhoven University of Technology created the 'world's initial livable 3D-printed apartments.' These houses in Eindhoven were constructed through a collaboration involving the university, the city municipality, and many other construction companies.

Gaia was constructed by the Italian 3D-printing company WASP. They constructed 3D printed houses that are compact units measuring 30 square meters, featuring an exterior shell crafted through 3D printing and internal timber beams supporting the wooden roof of each unit.

New Story is a non-profit organization based in the United States, which collaborated with the Texas-based technology company ICON to construct the first 3D printed village in Mexico, as part of their initiatives to address global homelessness. They constructed apartments featuring two bedrooms, a living room, a kitchen, and a bathroom. These 3D printed homes are designed to comfortably accommodate small families. A large-scale Vulcan II, which is a 10-meter-long 3D printer, was used to pure the concrete from the foundation to the top of the houses. This entire manufacturing process averaged around 24 hours per house.

DUS is a cabin measuring eight square meters in Amsterdam constructed by a Dutch architecture firm in 2016 using 3D printing technology, featuring unique amenities such as an internal bathtub. The architects chose eco-friendly bio-plastic materials for constructing the urban cabin, showcasing the potential of additive manufacturing in addressing temporary housing needs, particularly in the aftermath of natural disasters.

Mirreco, a biotechnology company headquartered in Perth, Australia, constructed multiple 3D-printed homes using hemp-based materials to explore the capabilities of industrial hemp. With the aid of other companies, they developed hemp panels suitable for construction projects. These panels can be directly produced using a 3D printer and used in building the framework of houses. The most important feature of this construction is the nature of the materials used, since after the demolition of the building all the materials can be recycled.

The PassiveDom House, developed by PassivDom, a startup operating out of Ukraine and California, is a solar-powered 3D printed home designed to produce water from the atmosphere. PassivDom claims that they can manufacture these homes using 3D printing technology in just eight hours and deliver them to customers on the same day. However, after the printing process, some additional finishing touches are necessary, requiring conventional building methods.

Sources: constructionkenya.com, dezeen.com

Media

- How the world’s first habitable 3D printed houses are made

Want to read more like this story?

Dubai plans to build the world's first 3D-printed mosque

May, 03, 2023 | NewsDubai aspires to build the world's first 3D-printed mosque, that will cover an area of 2,000 square...

Printout homes using new techniques: the rise of 3D-printed houses

Aug, 18, 2021 | NewsPalari Homes and Mighty Buildings company is using a new technique to build houses within 24 hours....

World’s largest 3D printed building in Florida completed

Jun, 20, 2023 | NewsPrinted Farms, renowned for constructing Florida's initial authorized 3D printed house in Tallahass...

A 3d-printed house to withstand strong earthquakes was built in 26 hours

Oct, 25, 2023 | NewsA team in Guatemala used 3D printing technology to construct an earthquake-proof house within a rem...

First 3D-printed building in Dubai

Jul, 29, 2019 | NewsThe first building realized via 3D printing technology in Dubai will be developed by Emaar Prop...

Melbourne: the first 3D-printed house in southern hemisphere

Jan, 18, 2022 | NewsThe first ever 3D-printed house in the southern hemisphere has been built in a Melbourne manufactur...

A 29-meter-long 3D printed bridge is under construction in the Netherlands

Apr, 05, 2021 | NewsThe world's longest 3D printed pedestrian concrete bridge is currently under construction in the...

New solution promises 90% cost reduction in concrete 3D printing materials

Dec, 22, 2021 | NewsConcrete 3D printing of building shells has grown considerably in the last few years, with more and...

Japan: The first railway 3D-printed building constructed within 2 hours

Jul, 22, 2025 | NewsOn Tuesday, July 22, the first 3D-printed train station building was constructed at Hatsushima Stat...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

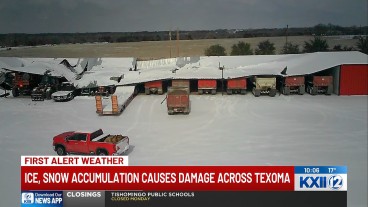

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran