MIT researchers developed glass bricks with the same strength as concrete blocks

Novel research from the Massachusetts Institute of Technology (MIT) demonstrates that 3D-printed glass bricks can be structurally sound, offering a sustainable alternative to traditional bricks and reducing carbon emissions. This groundbreaking method has the potential to revolutionize the construction sector by promoting circular construction, where materials are reused to minimize waste. They suggest that glass bricks could revolutionize construction, as these bricks can be assembled and disassembled like LEGO pieces. They need to find more sustainable materials for buildings and structures due to the high carbon emissions from the traditional materials that have been used until now.

The glass bricks are figure-eight shaped to interlock with one another, as Lego pieces, and effectively distribute stress, hence, this shape ensures that the structure will be stable. In addition, after extensive mechanical tests with industrial hydraulic presses, researchers concluded that the glass bricks are as strong as the concrete blocks as they withstood the same pressure and forces. The Assistant Professor of mechanical engineering at MIT, Becker, claims that glass can be reused repeatedly if it is kept in its pure form. He also added, that due to this glass feature they can make materials that can be reused indefinitely.

Researchers also described in their study the process that they are using to create the glass bricks, that is beginning with crushed bottles. Afterwards they melt the glass pieces in a specialized furnace before they load the Glass 3D Printer 3 (G3DP3). G3DP3 is an advanced machine that is developed by Evenline. The printer then constructs the glass into precise layers that shape the figure-eight bricks.

Moreover, the research team added an extra feature that is made from different material and attached it at the bottom of the bricks to address any structural issue and maximize the interlocking capabilities of the bricks.

According to the researchers, they argue that now they have tested the durability and the stability of the glass bricks in a safe environment. Therefore, they are planning to adapt this technology for larger infrastructures and if they succeed, they want to integrate the 3D-printed glass bricks onto real construction projects.

In all, this innovative research is emphasizing the need to stride to cleaner building practices, that in the future will lead to net zero carbon emissions from construction processes. In addition, the ability of these bricks to be easily assembled and disassembled enables buildings to be relocated with minimal effort, significantly reducing waste when relocation becomes necessary.

Sources: mit.edu, technologynetworks.com

Want to read more like this story?

A small-scale company in Zanzibar transforms waste glass into bricks

Jan, 23, 2018 | NewsThe initiative started as a way to deal with the large quantities of waste glass that are produced o...

Revolutionary glass bridge exhibit at the Corning Museum of Glass

Jul, 15, 2024 | NewsThe Corning Museum of Glass with the aid of the University of Pennsylvania will exhibit a revolutio...

Turning bio-solids into bricks

Feb, 05, 2019 | NewsA research team at RMIT University in Melbourne, Australia, has found a method to turn bio-solids in...

Unbreakable Glass Strong Like Steel

Nov, 09, 2015 | NewsJapanese scientists claim that they created a glass which is as strong as steel. Japanese scienti...

Engineering concepts behind the stability of famous masonry domes confirmed

May, 26, 2020 | NewsResearch conducted at Princeton University and the University of Bergamo unearths the technical sec...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

10 state-of-the-art sustainable materials that will alter construction industry

Jun, 10, 2024 | NewsIn 2024, sustainable materials become state-of-the-art in construction since the construction indus...

Barcelona, Spain: The first zero waste, near zero CO2 emission footprint, 3D-printed building

Jul, 29, 2024 | NewsThe first building created by earth-mix material and a 3D printer is being constructed at Valldaura...

Sustainable building materials and products: the latest trends

Jun, 28, 2023 | NewsArchitects and designers face numerous challenges when creating sustainable buildings or structures...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

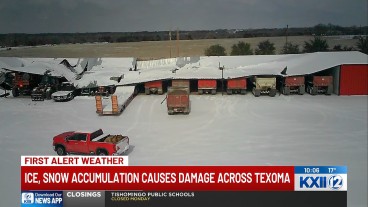

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran