Microspheres can improve concrete's mechanical properties

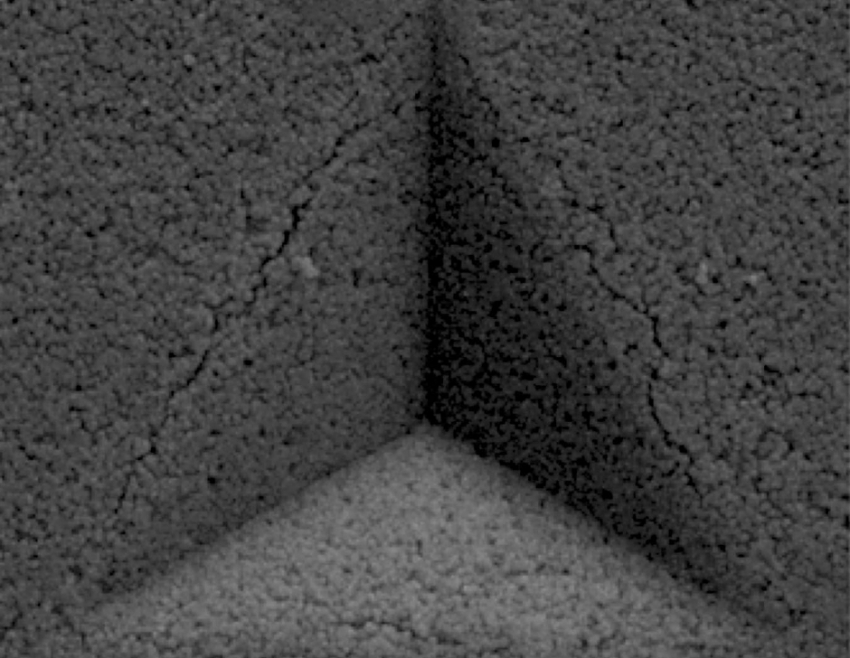

Researchers have developed micron-sized calcium silicate spheres that could increase concrete's strength and reduce its environmental footprint.

Concrete is the most-used synthetic material worldwide and its improvement could be highly beneficial. Rouzbeh Shahsavari, an assistant professor of materials science and nanoengineering in Rice University and Sung Hoon Hwang, a graduate student, explain that spheres are formed in a liquid mixture around nanoscale seeds of a common detergent.

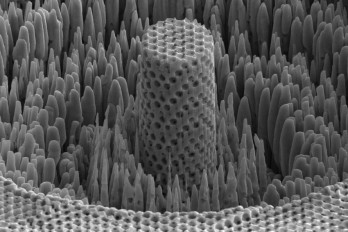

The spheres can be assembled to create solids that have better mechanical properties (strength, hardness, elasticity and durability) than Portland cement, the most common binder used in concrete. Authors state that their cost is low and their production requires less energy than cement. "These are very simple but universal building blocks, two key traits of many biomaterials. They enable advanced functionalities in synthetic materials. Previously, there were attempts to make platelet or fiber building blocks for composites, but this works uses spheres to create strong, tough and adaptable biomimetic materials. Sphere shapes are important because they are far easier to synthesize, self-assemble and scale up from chemistry and large-scale manufacturing standpoints," Shahsavari said.

Professor Shahsavari highlights the benefits of the spheres utilization: "Cement doesn't have the nicest structure. Particles are amorphous and disorganized, which makes it a bit vulnerable to cracks. But with this material, we know what our limits are and we can channel polymers or other materials in between the spheres to control the structure from bottom to top and predict more accurately how it could fracture." He also adds that the microscopic particles can be used for other engineering purposes like insulation or composite applications.

The diameter of the spheres can range from 100-500 nanometers, controlled by the selection of surfactants, solutions, concentrations and temperatures during manufacture. According to Shahsavari, shape and size of particles influences the mechanical properties of materials like concrete. "It is very beneficial to have something you can control as opposed to a material that is random by nature. Further, one can mix spheres with different diameters to fill the gaps between the self-assembled structures, leading to higher packing densities and thus mechanical and durability properties," he said.

If the utilization of spheres is realized in industry, manufacturers could use less concrete reducing the cost and the energy required to complete a construction.

Want to read more like this story?

Concrete Structures

Jan, 01, 2019 | EducationConcrete structures are constructions that utilize concrete as the primary building material. Conc...

New lightweight material has the strength of titanium

Feb, 22, 2019 | NewsResearchers have developed a sheet of nickel with nanoscale pores that has the strength of titanium...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

Zero-cement concrete will reduce the environmental impact in construction industry

Aug, 08, 2024 | NewsDue to the climate crisis and the high CO2 emissions of concrete, engineers and scientists are seek...

10 state-of-the-art sustainable materials that will alter construction industry

Jun, 10, 2024 | NewsIn 2024, sustainable materials become state-of-the-art in construction since the construction indus...

Composite structures

Sep, 07, 2023 | EducationComposite structures refer to constructions that are composed of two or more distinct materials co...

Bio-inspired composite cement: a new material to increase durability using natural principles

Jun, 28, 2024 | NewsPrinceton’s university engineers developed a new composite cement inspired by oyster and abalone sh...

Concrete is a climate disaster and thus it’s time to clean it up

Oct, 29, 2021 | NewsFor soaring bridges, dramatic skyscrapers and even the path around your local park, builders love c...

Concrete that traps CO2 emissions for good

Jul, 16, 2018 | NewsA new method to produce concrete that traps harmful CO2 emissions and increases the compression stre...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

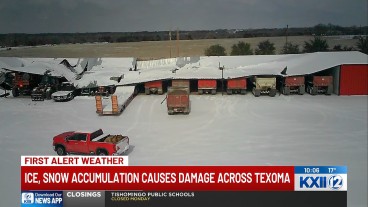

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran