ETH Zurich: Introducing a new robotic method in 3D-printing field as a more sustainable alternative

ETH Zurich researchers introduced a revolutionary 3D-printing technique that is known as Impact Printing. This robotic method uses natural materials like sand, silt, clay, and gravel. This innovative approach aims to reduce carbon emissions and offers a cost-effective alternative to traditional 3D printing methods. The most significant feature of this method is that it allows structures to be made from locally sourced, recyclable earth materials, reducing both environmental impact and expenses.

An SNSF Bridge Fellow at ETH Zurich, Lauren Vasey stated that the research team developed a robotic tool and process to transform excavated materials from construction sites into building products. Contrary to conventional 3D printing, that relies mostly on cement-reinforced materials, “Impact Printing” is developed to use only natural components, minimizing the use of additives. Specifically, during the process, finer materials like clay serve as binders, while coarse materials such as sand and gravel provide strength, allowing for seamless movement through the robotic system without clogging.

To start the printing process, they provide the robotic tool with a digital blueprint that will guide it to project the material at high speeds (up to 32 feet per second). Then once printing starts the robotic tool builds the structure layer by layer without the need for cement. This method yields durable structures, including walls up to 6.5 feet tall capable of supporting additional load. Despite its compressive strength (around 2 MPa) being lower than concrete, it is suitable for constructing two-story structures.

In all, ETH Zurich plans to commercialize “Impact Printing” through a prefabrication facility, while they are anticipating market readiness within three years. It should be noted that, the University of Virginia also introduced a 3D-printable concrete alternative, using a graphene-enhanced clay mix, that is promising 31% less emissions while another project by TU Berlin and Brunel University integrates recycled glass into 3D printing concrete, enhancing strength and thermal insulation.

Sources: 3dprintingindustry.com, parametric-architecture.com

Want to read more like this story?

New solution promises 90% cost reduction in concrete 3D printing materials

Dec, 22, 2021 | NewsConcrete 3D printing of building shells has grown considerably in the last few years, with more and...

Dubai plans to build the world's first 3D-printed mosque

May, 03, 2023 | NewsDubai aspires to build the world's first 3D-printed mosque, that will cover an area of 2,000 square...

A 29-meter-long 3D printed bridge is under construction in the Netherlands

Apr, 05, 2021 | NewsThe world's longest 3D printed pedestrian concrete bridge is currently under construction in the...

Printout homes using new techniques: the rise of 3D-printed houses

Aug, 18, 2021 | NewsPalari Homes and Mighty Buildings company is using a new technique to build houses within 24 hours....

The world’s most exceptional 3D printed homes

Apr, 10, 2024 | News3D printing technology is a revolution at the construction sector, enabling builders to fabricate h...

First 3D-printed building in Dubai

Jul, 29, 2019 | NewsThe first building realized via 3D printing technology in Dubai will be developed by Emaar Prop...

Tanzania: They plan to construct about 50 3D-earth printed buildings

Aug, 14, 2024 | NewsToday, the construction industry is characterized by the continuously increasing use of 3D-printing...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

Japan: The first railway 3D-printed building constructed within 2 hours

Jul, 22, 2025 | NewsOn Tuesday, July 22, the first 3D-printed train station building was constructed at Hatsushima Stat...

Trending

Spectacular interchanges around the world

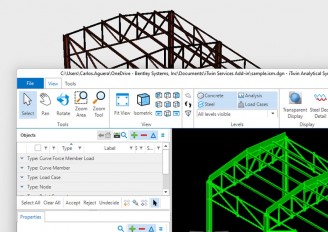

New Release - STAAD.Pro 2024 - 2

ADINA 2025 for Structural WorkSuite

ADINA 2025 New Release!

Concrete Buildings as Rechargeable Batteries

Powerful earthquake shakes central Philippines, dozens killed

Indonesia school collapse: three fatalities and dozens injured