Plans for mini nuclear reactors in UK by Rolls-Royce

Rolls-Royce plans to construct 15 mini nuclear reactors in the UK in the forthcoming years.

Small modular reactors or SMRs, are much smaller facilities than conventional nuclear reactors. They are assembled in a factory and delivered on-site.

On Friday, January 24, 2020, Paul Stein, chief technology officer for Rolls-Royce, announced that the company is currently leading an association that aims to implement mini nuclear reactors technology in Britain in an effort to address energy demand with low carbon emissions.

Moreover, the consortium which has been introduced claims that the nuclear facilities will be financially efficient and capable of competing with renewable sources such as wind power. The prefabricated segments will be assembled using robotics technology making the project more reliable and significantly reducing the costs. "The trick is to have prefabricated parts where we use advanced digital welding methods and robotic assembly and then parts are shipped to site and bolted together," Stein, stated.

Rolls-Royce's purpose is to establish 10-15 nuclear reactors in the U.K. beginning at sites in Cumbria or Wales which were previously used for nuclear energy production. "The obvious sites to put them are what we call brown-field sites – sites where we're running elderly or decommissioned nuclear power stations. There are two sites in Wales and one in the northwest of England. Eventually in the UK, we’ll be rolling out 10 to 15," Katie Prescott, a business correspondent at BBC News, stated.

SMRs establishment is so efficient that every small city could have a reactor on its own. The problem that arises is a potential attack on the reactor that could result in devastating consequences.

The proposal is the first to subserve the deteriorating nuclear industry in the UK which is currently in crisis as renewable energy sources thrive. During the past years, Japanese firms Toshiba and Hitachi have abandoned their nuclear projects in England due to a lack of funding.

According to predictions, the endeavor could contribute $68 billion in UK's economy, $327 billion in exports and create 40,000 new working positions in the next 30 years.

Nevertheless, there are some people that question the efficiency of the project. According to Paul Dorfman, an Honorary Senior Research Fellow at the Energy Institute, University College London (UCL), the cost of maintaining many small reactors could prove to be higher than expected. "The potential cost benefits of assembly line module construction relative to custom-build on-site construction may prove overstated. Production line mistakes may lead to generic defects that propagate throughout an entire fleet of reactors and are costly to fix. It's far more economic to build one 1.2 GW unit than a dozen 100 MW units," Dr. Dorfman, stated.

Sources: BBC, Forbes, NewAtlas

Media

- Rolls-Royce Small Modular Reactor

- UK Nuclear SMR Consortium

Want to read more like this story?

Japan Begins Building Ice Wall at Fukushima Nuclear Plant

Jun, 05, 2014 | NewsConstruction is underway on a 1.5-kilometer long ice wall surrounding the Fukushima Nuclear Plant in...

The Building Material Of The Device Of ITER

Jul, 15, 2015 | NewsAt the construction site of the International Thermonuclear Experimental Reactor, known as ITER in s...

New Safe Confinement Arch To Cover Chernobyl Reactor 4

May, 02, 2014 | NewsThe Chernobyl nuclear disaster occurred 28 years ago on April 28, 1986. Construction is now underway...

Renewable energy thrives during COVID-19 lockdown in Europe

Apr, 10, 2020 | NewsCOVID-19 has highly affected electricity demand globally. When it comes to Europe, new data show th...

Modular construction: An uprising project method

Jul, 20, 2018 | NewsExpects believe it is time to replace the conventional way a construction project is executed with a...

The prospects for carbon-neutral buildings

Oct, 27, 2023 | NewsIn the United Kingdom, buildings account for 33% of greenhouse gas emissions and 40% of global ener...

Digitalization could assist the construction industry reducing its carbon emissions

May, 28, 2024 | NewsIt is well known that the global construction industry significantly contributes to the world's car...

Smart construction: How superstructures are built in just 11 days

Mar, 06, 2025 | NewsThe construction industry has undergone significant changes in recent years as digital transformati...

Denmark's plans for windfarm megaproject

Dec, 19, 2019 | NewsDenmark is planning to establish a large wind farm that will surround an artificial island. The m...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

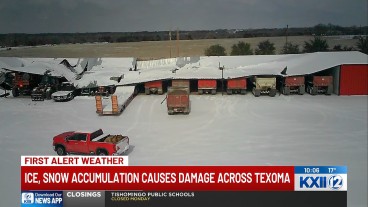

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran