Jet Grouting Project by Keller on Brooklyn Bridge Manhattan Approach Arches Featured

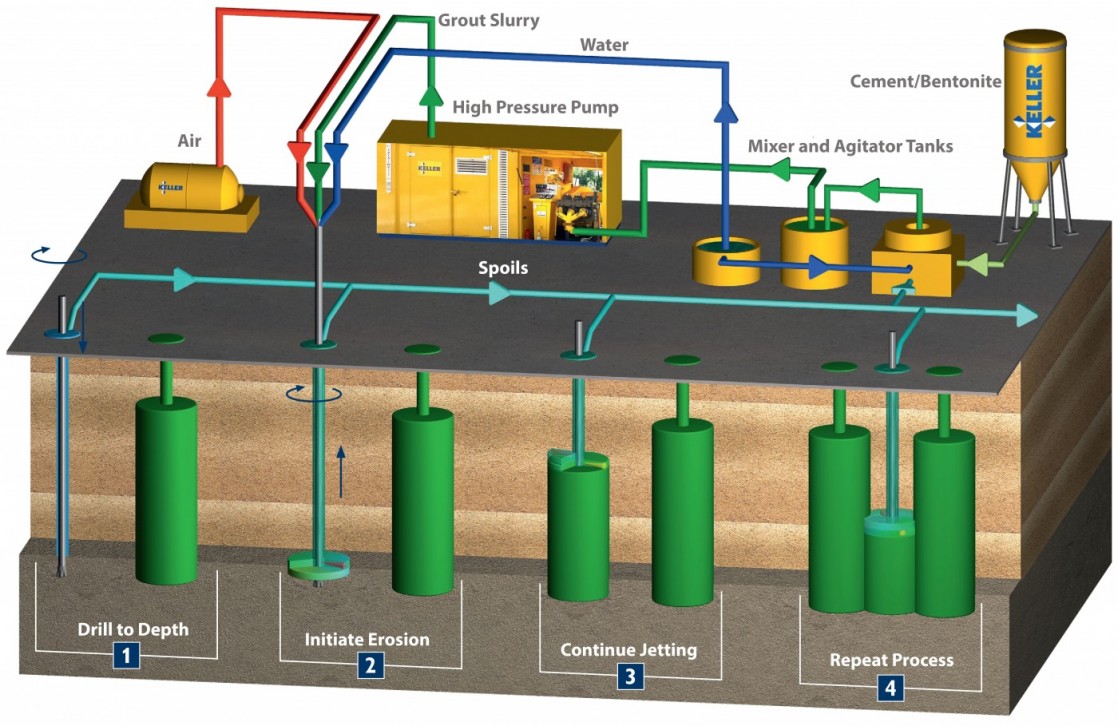

Keller team is working on the iconic Brooklyn Bridge in New York City, using jet grouting to rehabilitate the Manhattan approach arches. Mobilization began in May 2020 and production is expected to finish in Fall of 2021.

- Effective across the widest range of soil types of any grouting system, including silts and most clays

- Ability to construct soilcrete in limited spaces and around subsurface obstacles such as utilities

- Low headroom equipment enables construction in limited spaces such as basements

- Can target specific soil layers at depth without having to treat soils above

- Jet grouting can be combined with other techniques to provide a comprehensive and cost-effective geotechnical solution

- Can usually be done without disrupting normal facility operations

- Containerized, highly mobile support equipment reduces mobilization and demobilization costs and time

Source: Keller embraces highly challenging project during pandemic

Want to read more like this story?

Chaplin Station Grouting Project

Oct, 10, 2022 | NewsWhen unexpected movement and ground disturbance occurred following drilled shaft installation, Kell...

Keller brings expertise and environmental innovation to Norway hospital project

Aug, 11, 2021 | NewsIt’s a complex project. The new buildings will be right in the heart of the campus, linked to exist...

Keller wins global projects award for work on the Follo Line Project in Norway

Oct, 15, 2019 | NewsKeller's work on the prestigious Follo Line Project in Norway has won an Award of Merit in the Rail...

Keller's Neutrogel®: A new cheaper and greener grouting material

Apr, 02, 2021 | NewsA new grouting material called Neutrogel® that has minimal impact on soil and groundwater, a much l...

Design-build grouting program for a water-tight excavation at Baltimore CSX

Aug, 31, 2022 | NewsIn downtown Baltimore, increased flooding and impacted train operations led to a complete replaceme...

North American Keller's Companies joined together as KELLER

Jan, 10, 2020 | NewsAs of January 1, 2020, North America Keller companies Bencor, Case Atlantic, Case Foundati...

South Shore Water Reclamation Facility Excavation Support Project

Sep, 26, 2022 | NewsThe South Shore Water Reclamation Facility on the coast of Long Island, New York, is undergoing a m...

Keller wins ABC New Orleans 2022 Excellence in Construction award

Jan, 05, 2023 | NewsKeller was contracted to install support of excavation for launch and receiving shafts to connect a...

KELLER keeps running projects safely despite the COVID-19 outburst

May, 13, 2020 | NewsKeller teams across the world are doing everything they can to mitigate the impact of the coronavir...

Form

Looking for more information? Fill in the form and we will contact Keller for you.

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran