Hayward Baker is helping to preserve and restore a historic US Government facility in Southern California.

Company's crews are installing micropiles to underpin the foundations & prevent further settlement of the structure. Micropiles were chosen due to the difficult subsurface drilling conditions, the tight site access, and the concern that vibration may damage the structure

Micropiles are also known as minipiles, pin piles, needle piles, and root piles. The micropile casing generally has a diameter in the range of 3 to 10 inches. Typically, the casing is advanced to the design depth using a drilling technique. Reinforcing steel, typically an all-thread bar, is inserted into the micropile casing. High-strength cement grout is then pumped into the casing. The casing may extend to the full depth or end above the bond zone with the reinforcing bar extending to the full depth. The finished micropile (minipile) resists compressive, uplift/tension, and lateral loads and is typically load tested in accordance with ASTM D 1143 (compressive), ASTM D 3689 (uplift/tension), and ASTM D 3966 (lateral). Capacities vary depending on the micropile size and subsurface profile. Allowable micropile compressive capacities of more than 500 tons have been achieved.

This technique has been used to support most types of structures. Hayward Baker’s micropile drill rigs allow installation in restricted access and low headroom interiors, allowing facility upgrades with minimal disruption to normal operations.

Click here for more information on micropiles.

Source: Hayward Baker

Source: Hayward Baker

Want to read more like this story?

Hayward Baker works on iconic US landmark

Dec, 04, 2017 | NewsWhen a St Louis contractor ran into an unexpected problem on the site of one of America’s most iconi...

North America’s leader in specialty geotechnical construction

Dec, 23, 2016 | NewsHayward Baker, Inc., a Keller Company, helps owners and developers overcome challenging foundation...

Hayward Baker expands its regional presence with new office facility in Phoenix

Feb, 05, 2019 | NewsHayward Baker, North America's leader in geotechnical construction, announces the opening of a new o...

Micropile solution by Hayward Baker

Nov, 30, 2018 | NewsHayward Baker's value-engineered macropile alternative to the originally-specified drilled shafts si...

Hayward Baker has a new logo as part of Keller Group (video)

Feb, 23, 2017 | NewsHayward Baker has a fresh, new logo as part of Keller Group of companies. Hayward Baker is a memb...

Hayward Baker: Rolling Hills Wind Farm

Sep, 25, 2018 | NewsHayward Baker’s ability to assemble experienced personnel and resources in-house to perform all tech...

Drilled shafts and Micropiles Project at Logan International Airport, Massachusetts

Jan, 27, 2023 | NewsAs part of Massport’s 4-year Capital Program, a multi-billion-dollar upgrade initiative was launche...

Titan’s Practice Facility Sidewalk by Hayward Baker

Mar, 06, 2019 | NewsThe Tennessee Titans football organization required a new sidewalk and path alongside a lake to conn...

Hayward Baker, Inc. Organizer of Minneapolis, MN Geotechnical Seminar

Apr, 05, 2017 | NewsHayward Baker will be in the Twin Cities area on May 17th for our Minneapolis, MN Geotechnical Semin...

Form

Looking for more information? Fill in the form and we will contact Keller for you.

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

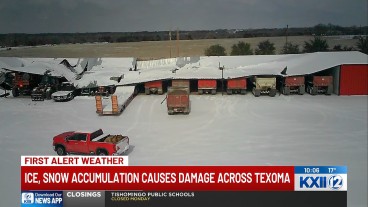

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran