Bond-free CFRP as a new concept for strengthening steel

According to a new study, buckling performance and compression capacity of structural steel elements can be enhanced using bond-free carbon fiber reinforced plastic (CFRP) laminates.

CFRP offers a range of advantages such as its light weight and high strength, as well as its fatigue and corrosion resistances. Therefore, it is preferable for strengthening steel members. Until today, CFRP is mainly being attached to steel surfaces using adhesive. This bonding technique apart from the fact that it requires very careful steel surface treatment before the CFRP installation, it is vulnerable to environmental exposure during service life of CFRP, something that can cause significant decrease in strengthening.

The research conducted by the Structural Engineering Laboratory of the Department of Architecture and Civil Engineering at Toyohashi University of Technology showed that, alternatively, if CFRP is not bonded onto the surface of the steel element, it can offer structural strength due to its flexural rigidity.

The experiments showed that the unbonded CFRP strengthening method leads to a delay of the buckling phenomenon, as well as to an increase of the compression capacity of steel bars. The results of this study make the research team believe that the bond-free CFRP method can be applied also in fields such as aerospace engineering, and in the automotive and marine industries. The study was recently published in Construction and Building Material journal.

Source: phys

Want to read more like this story?

The future of steel production and steel structure construction

Nov, 27, 2022 | NewsThis article will explore four technologies that are helping shape the future of steel construction...

Steel Structures

Jan, 01, 2019 | EducationThe term “steel structures” refers to constructions that rely primarily on steel as the main build...

How long can fiber reinforced polymer sustain concrete structures? A question that is answered by scientists

Oct, 14, 2021 | NewsIt is a fact that, in modern society, the majority of our infrastructure (buildings, bridges, tunne...

Using a by-product of steel production to enhance the mechanical properties of concrete

Jan, 15, 2020 | NewsAccording to a new study, the utilization of a by-product of steel making may be used in concrete m...

Potential problems and solutions in steel structures

Nov, 09, 2023 | NewsEvery construction material, including steel, is sensitive to various issues. Although steel remain...

Strengthening and repairing concrete structures using paper-thin carbon fiber reinforced polymers

Apr, 07, 2021 | NewsA new method to strengthen and repair deficient bridges with paper-thin material has been recogni...

INSTANT steel

Aug, 27, 2014 | Software

Ductility in Steel Beams Improved by Geometric Cutouts

Mar, 23, 2015 | NewsThe ability of steel buildings to bend without fracturing, or ductility, allows for extreme lateral...

Bentley Webinar | Mastering industrial steel structure design with STAAD.Pro and RAM Connection

Sep, 25, 2024 | EventIn the evolving field of structural engineering, mastering advanced techniques for seismic and stab...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

San Francisco to highly reduce buildings environmental impact

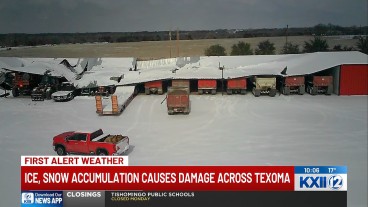

Multiple structure collapses across Texoma due to ice weight

5.2-magnitude earthquake strikes Asaluyeh in Southern Iran