Applying ground freezing in major New York tunnel project Featured

Keller applied ground freezing in the largest infrastructure project ever conducted in Suffolk County, New York.

Keller is one of the few companies in North America to offer ground freezing technique application. It’s also the only one to carry out its own drilling for the refrigeration pipes and to run its own in-depth analysis and modeling to ensure the highest levels of quality control.

Learn more about Keller North America wide range of services

A 4.2-kilometer (2.6-mile) stretch of outfall pipe pumping millions of gallons of treated wastewater under the Great South Bay is being replaced. A $187 million construction contract was awarded by County officials in May 2018 to a joint venture of OHL, Posillico and SELI Overseas. Keller was handed the subcontract for temporary excavation support and groundwater control on the tunnel’s launching and receiving shafts.

The technique was used to provide excavation support and groundwater control on two shafts for the tunneling project. The 38-meter-deep, 10,5-meter internal diameter launch shaft specified ground freezing, in large part due to the amount of space available at the Bergen Point Wastewater Treatment Plant, where the tunnel starts. “It’s a small site, with room for just one rig, so there isn't really space to carry out a diaphragm wall,” Keller’s Director of Ground Freezing, Joe Sopko, mentioned.

A highly efficient design

The tunneling project required a 6-meter thick frozen bottom plug as a result of the permeable sands that are deposited at the bottom of the proposed launch shaft.

Thorough laboratory testing and modeling enabled Keller to create a highly efficient design, with the optimum number and spacing of refrigeration pipes. With such a large part of the cost going into the drilling, it was vital to get the specifications just right.

“Initial frozen soil compression tests provided to us reported lower-than-expected frozen soil strengths and didn’t take into consideration groundwater salinity. So we collected our own soil samples, subcontracted frozen lab tests, and used a time-dependent heat-transfer model to evaluate the time needed to freeze the perimeter and the bottom plug. This was coupled with a model that included groundwater flow to evaluate the effects on the formation of the frozen earth wall," Sopko, stated.

Striking a balance

49 pipes were installed into precisely drilled and aligned holes on 0.9-meter centers around the perimeter of the launch shaft, with nine in the middle, to depths of 45 meters. The pipes were then used to circulate a calcium chloride brine, chilled to -30ºC to an exact flow rate for six weeks.

According to Shawn Coughlin, Keller Senior Project Manager, the "sequencing was more complicated than a typical ground freezing project. The design was based on freezing the center and perimeter pipes simultaneously. Then, once the bottom was frozen to the right temperature, we removed the interior pipes to make excavation easier. The perimeter pipes were sufficient to maintain the freeze".

A team that’s second to none

Keller returned in November 2019 to work for the receiving shaft after completing the launch shaft in 2018.

This time, 39 pipes were installed around the perimeter with seven in the center. In addition, 24 pipes were installed in a grid pattern to freeze a break-in block for the tunnel boring machine. Freezing is now complete and overall, the project has been a significant success.

Source: Keller

Want to read more like this story?

Artificial ground freezing – past, present, and future

Jan, 19, 2023 | EventJoin Keller for the first webinar in their 2023 series titled "Artificial ground freezing – past, p...

Port Mann Water Main Supply Tunnel

Dec, 06, 2024 | NewsKeller developed a liquid nitrogen ground freezing solution that allowed for safe access to inspect...

A unique in-tunnel grouting project by Keller at Merbourne's Metro Tunnel

Jun, 08, 2021 | NewsAfter months of careful design planning and on-site expertise, Keller has successfully completed a...

Keller wins ABC New Orleans 2022 Excellence in Construction award

Jan, 05, 2023 | NewsKeller was contracted to install support of excavation for launch and receiving shafts to connect a...

South Shore Water Reclamation Facility Excavation Support Project

Sep, 26, 2022 | NewsThe South Shore Water Reclamation Facility on the coast of Long Island, New York, is undergoing a m...

North American Keller's Companies joined together as KELLER

Jan, 10, 2020 | NewsAs of January 1, 2020, North America Keller companies Bencor, Case Atlantic, Case Foundati...

Chaplin Station Grouting Project

Oct, 10, 2022 | NewsWhen unexpected movement and ground disturbance occurred following drilled shaft installation, Kell...

Improving weak soils with columns of compacted crushed concrete

Jun, 17, 2021 | NewsKeller’s committed to reducing its impact on the environment by offering clients more sustainable s...

Beacon Hill Station Dewatering Project

Aug, 21, 2024 | NewsDewatering wells effectively lowered groundwater levels up to 60 ft before excavation of the shaft...

Form

Looking for more information? Fill in the form and we will contact Keller for you.

Trending

Spectacular interchanges around the world

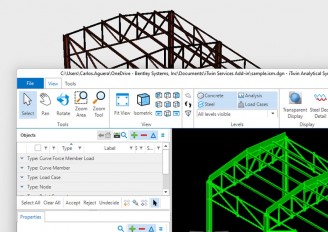

New Release - STAAD.Pro 2024 - 2

ADINA 2025 for Structural WorkSuite

ADINA 2025 New Release!

Concrete Buildings as Rechargeable Batteries

Powerful earthquake shakes central Philippines, dozens killed

Indonesia school collapse: three fatalities and dozens injured