Cement becomes stronger when it has molecular defects

Scientists have found a way to turn weakness into strength

Scientists have found a way to turn weakness into strength

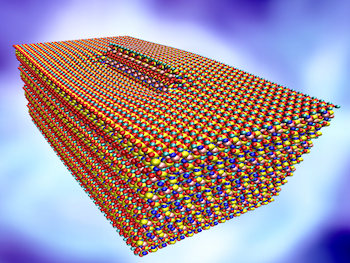

Researchers at Rice University in Houston are trying to make concrete stronger, tougher and better able to deform without cracking under stress. To do this they have studied the internal structure of tobermorite, a naturally occurring crystalline analog to the calcium-silicate-hydrate (C-S-H) that makes up cement, which in turn holds concrete together. Using advanced microscopy techniques, they noticed twisting imperfections in its layers – the so called screw dislocations. When applying force, they observed that defect-free tobermorite deformed easily as water molecules caught between its layers allowed them to glide past each other. In contrary, in particles with screw defects, each layer only glided so far before being locked into place by the tooth-like core dislocations, and as the buck was passed to the next layers, stress was effectively guided out to the edge, instead of being absorbed and creating a crack. Even more incredible, the imperfections would spread to neighboring molecules, increasing the material’s flexibility.

“What first comes to mind is that defects are bad for material,” says Rouzbeh Shahsavari, an assistant professor of civil and environmental engineering and materials science and nanoengineering at Rice University. But this was certainly not the conclusion that his team, who experimented with computer models of tobermorite featuring such imperfections, came to. Their findings were recently published in the American Chemical Society journal ACS Applied Materials and Interfaces.

“The insight we get from this study is that unlike the common intuition that defects are detrimental for materials, when it comes to complex layered crystalline systems such as tobermorite, this is not the case,” said Shahsavari. “Rather, the defects can lead to dislocation jogs in certain orientations, which act as a bottleneck for gliding, thus increasing the yield stress and toughness. These latter properties are key to design concrete materials, which are concurrently strong and tough, two engineering features that are highly desired in several applications. Our study provides the first report on how to leverage seemingly weak attributes — the defects — in cement and turn them to highly desired properties, high strength and toughness’’. The team believes that by optimizing these screw dislocations, the concrete produced could be twice as strong.

A screw dislocation disrupts the regular rows of atoms in tobermorite, a naturally occurring crystalline analog to the calcium-silicate-hydrate that makes up cement. Rice University scientists simulated tobermorite to see how it uses dislocations to relieve stress.

Courtesy of the Multiscale Materials Laboratory

Source: Rice University News

Want to read more like this story?

Concrete Structures

Jan, 01, 2019 | EducationConcrete structures are constructions that utilize concrete as the primary building material. Conc...

New lightweight material has the strength of titanium

Feb, 22, 2019 | NewsResearchers have developed a sheet of nickel with nanoscale pores that has the strength of titanium...

Zero-cement concrete will reduce the environmental impact in construction industry

Aug, 08, 2024 | NewsDue to the climate crisis and the high CO2 emissions of concrete, engineers and scientists are seek...

Bio-inspired composite cement: a new material to increase durability using natural principles

Jun, 28, 2024 | NewsPrinceton’s university engineers developed a new composite cement inspired by oyster and abalone sh...

Concrete is a climate disaster and thus it’s time to clean it up

Oct, 29, 2021 | NewsFor soaring bridges, dramatic skyscrapers and even the path around your local park, builders love c...

Microspheres can improve concrete's mechanical properties

Oct, 04, 2018 | NewsResearchers have developed micron-sized calcium silicate spheres that could increase concrete's stre...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

Understanding and manipulating nanolayer composites behavior of Pearlite

Jan, 27, 2019 | NewsScientists from Kanazawa University in Japan have found a method to increase the ductility of Pearli...

Composite structures

Sep, 07, 2023 | EducationComposite structures refer to constructions that are composed of two or more distinct materials co...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Spectacular interchanges around the world

Maine Medical Center

Buildings Prone to Earthquakes

Roof collapse at Curragh Coal Mine leaves one worker missing