Concrete is a climate disaster and thus it’s time to clean it up

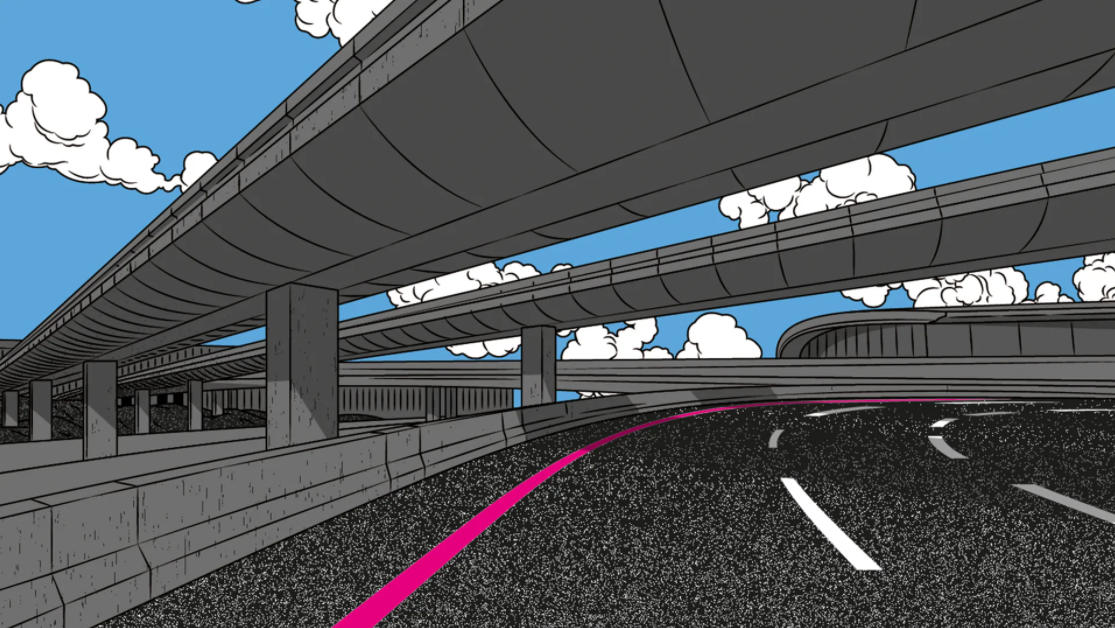

For soaring bridges, dramatic skyscrapers and even the path around your local park, builders love concrete, making it the most-used building material in the world – but producing the cement used in most concrete accounts for eight per cent of global greenhouse gas emissions.

The construction industry is desperate for a cleaner solution, with both startups and manufacturing giants developing ways to slash emissions, but the nature of the material and how it's made means net-zero concrete may not be possible.

Concrete is made from materials such as sand, rocks and aggregate glued together by cement, and for the last 200 hundred years that's largely meant Portland cement, an English invention that changed how we build. But there's a problem: to produce Portland cement, limestone is heated to 1,450 degrees Celsius, sparking a chemical reaction that drops a carbon dioxide molecule from the limestone, also called calcium carbonate.

"The inherent chemical reactions in this process release huge amounts of carbon dioxide – there's no way to get away from that," says Brant Walkley, lecturer in chemical engineering at University of Sheffield. He adds that half of the emissions from producing cement come from this process. "For every molecule of limestone that is used to make Portland cement, a molecule of carbon dioxide is released."

One solution is to add supplementary materials, such as blast-furnace slag from steel production, fly ash from coal power plants, silica fume, calcined clays and other industrial wastes. Not only does that keep these wastes and byproducts out of landfill, but it means less cement is needed, slashing emissions by as much as half.

Cement can also be made without limestone. Alternatives such as geopolymers and calcium sulphoaluminate don't drop off that damaging carbon molecule, says Kevin Paine, professor at the University of Bath, but there's less of the necessary raw materials around the world. "None of them can be made at the scale we currently need," he says. Plus, switching production systems is expensive for the industry, meaning progress has been slow.

That means we can't yet – if ever – entirely ditch Portland cement, but there are other ways to reduce its impact. Canadian startup CarbonCure Technologies injects carbon dioxide into concrete while mixing it, not only trapping the gas but reducing the volume of cement required. "Once injected, the CO2 chemically converts into a mineral, which permanently eliminates the CO2 and actually improves the concrete’s compressive strength," says Dean Forgeron, vice president of engineering. The technique shaves off up to six per cent in emissions, the company says, saving 125 tonnes of CO2 when making a mid-rise building.

Luigi Di Sarno, of the Resilient and Sustainable Infrastructure group at the University of Liverpool, argues that clever design could reduce the need for maintenance and replacement of concrete in buildings, bridges and water-logged infrastructure such as flood defence walls, helping to slash carbon emissions. His self-healing concrete, called BIOCOREWALLS, patches cracks using bacteria that produces limestone when it comes into contact with water, extending the life of infrastructure built with concrete by 30 per cent.

Tweaked recipes, cement alternatives, carbon curing and self-healing designs will all help, but reducing our use of concrete in the first place could be the simplest way to slash emissions. Bridges, skyscrapers and nuclear power plants require concrete, but why are we using this precision-engineered material to make footpaths or retaining walls? "If we optimise its use, that will improve its sustainability, because you're not wasting that performance and creating CO2 emissions that weren't necessary," says Walkley.

Sources: wired.co.uk, dailyadvent.com

Want to read more like this story?

Zero-cement concrete will reduce the environmental impact in construction industry

Aug, 08, 2024 | NewsDue to the climate crisis and the high CO2 emissions of concrete, engineers and scientists are seek...

Concrete that traps CO2 emissions for good

Jul, 16, 2018 | NewsA new method to produce concrete that traps harmful CO2 emissions and increases the compression stre...

Cement's production high environmental footprint

Jul, 24, 2019 | NewsThe production of cement results in more pollution in the environment than all the trucks and just 1...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

The world’s first carbon concrete building constructed by researchers in Germany

Nov, 10, 2022 | NewsThe first building made of carbon-reinforced concrete was inaugurated in September after two and a...

Concrete Structures

Jan, 01, 2019 | EducationConcrete structures are constructions that utilize concrete as the primary building material. Conc...

Less concrete in building design with the aid of AI

Sep, 09, 2023 | NewsConcrete is one of the most widely used construction materials worldwide. The concrete industry con...

Boston: Innovative cement used on a large-scale building marks a new era

Apr, 09, 2024 | NewsSublime Systems is the most innovative sustainability company of 2024 as it was recognized by Fast...

Steel or Timber? Carbon footprint of truss structures can be reduced with the aid of new studies

Nov, 29, 2021 | NewsBuildings contribute significantly to global warming, not just in their ongoing operations but in t...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Spectacular interchanges around the world

Maine Medical Center

Buildings Prone to Earthquakes

Roof collapse at Curragh Coal Mine leaves one worker missing