ADINA offers advanced material models in response to the need for advanced polymers in challenging engineering applications. To verify the results, both advanced material models and robust finite element solvers are employed. More specifically, the consideration of viscoelastic (time-dependent) effects becomes crucial if polymeric components are used in service.

For instance, biomedical applications increasingly use materials like ultra-high molecular weight polyethylene, while industrial sealing and bearing applications benefit from polytetrafluoroethylene (Teflon) due to its low friction, chemical inertness, and high resistance to temperature, corrosion, and stress cracking. These components frequently experience significant deformations in scenarios involving contact, temperature variations, and other nonlinearities. Therefore, a thorough comprehension of their viscoelastic behavior is essential.

To meet customers' needs, ADINA provides support for the Bergström-Boyce and Three-Network viscoelastic material models. These advanced models enable users to accurately capture the intricate viscoelastic behaviors of polymeric components. ADINA's powerful solvers, comprehensive element library, and multiphysics capabilities allow users to fully utilize these material models for optimal simulations.

Benchmark

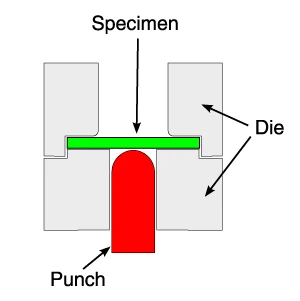

The small punch test is a well-established technique for material characterization. It involves placing a disk-shaped specimen within a die and then applying a punch against the specimen. The punch is driven at a controlled rate of 0.5mm/min, and the reaction force is recorded as the displacement progresses. In this particular study, the material being tested is a high-density polyethylene. The experimental setup is depicted in Figure 1.

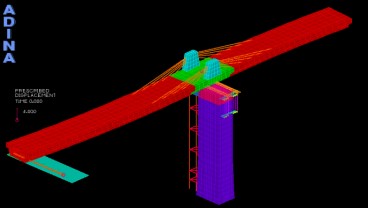

To simulate the material behavior during testing, ADINA's Three-Network model was utilized, with material parameters obtained from Bergström and Bischoff [1]; these models take into account the frictional contact effects. ADINA employs powerful, higher-order u/p elements that effectively prevent volumetric and shear locking, ensuring accurate results even in cases of severe deformation.

Figure 2 shows a comparison between the predictions from both the 3D-solid and axisymmetric analyses and the experimental results [1]. Remarkably, ADINA's implementation of the Three-Network model closely matches the experimental data for polyethylene in both the three-dimensional and axisymmetric two-dimensional cases. The axisymmetric model runs faster, but it is limited in capturing any asymmetric modes that might be induced, especially under extreme compressive stresses.

Overall, ADINA's Three-Network model proves to be a reliable tool for predicting material behavior in the small punch test, showing excellent agreement with experimental data for high-density polyethylene.

Thermal Effects

The Bergstrom-Boyce and Three-Network material models are capable of incorporating thermal effects, such as expansion and temperature-dependent viscoelastic behaviors. Furthermore, these models consider the dissipative nature of viscoelastic materials, meaning they generate heat during deformation. ADINA can accurately predict the internal heat generation through fully-coupled thermomechanical analysis.

In Figure 3, the Three-Network model is utilized with ADINA's 3D-shell element to simulate a rubber CV-joint boot. This comprehensive model takes into account self-contact and temperature effects within a fully-coupled thermomechanical analysis. The internal dissipations within the material are considered as heat generation in this analysis.

Conclusion

With the increasing sophistication of designs and the growing significance of complex material behaviors in determining overall performance, the selection of suitable material models for analysis becomes crucial. ADINA provides a comprehensive library of advanced material models, alongside state-of-the-art finite element formulations, solvers, and contact algorithms. These tools can be confidently employed in conjunction with advanced material models for various multiphysics applications.

References

- J.S. Bergström and J.E. Bischoff, "An Advanced Thermomechanical Constitutive Model for UHMWPE," Int. J. Struct. Changes Sol., 2:31–39, 2010.

- J.S. Bergström and M.C. Boyce, "Constitutive modeling of the large strain time–dependent behavior of elastomers," J. Mech. Phys. Solids, 46:931–954, 1998.

Sources: blog.virtuosity.com, adina.com, polymerfem.com

Want to read more like this story?

Using sophisticated material models in ADINA software

Jul, 08, 2023 | NewsSophisticated material models and reliable finite element solvers are necessary when using advanced...

Domed roof analysis of a railway station

Apr, 28, 2023 | NewsSouthwest Jiaotong University studied the structural integrity of the roof of a huge railway statio...

ADINA 2025 New Release!

May, 13, 2025 | NewsBentley Systems announced a new major release of ADINA. For a complete list of changes see ADINA...

ADINA Structures

Jun, 03, 2022 | Software

ADINA 2024 New Release!

Sep, 06, 2024 | NewsProduct versioning for Bentley Systems is now based on the calendar year of the major release accor...

ADINA Joins Structural WorkSuite: Unlocking Advanced Nonlinear and Multiphysics Analysis

Oct, 27, 2025 | NewsBentley Systems is excited to introduce Structural WorkSuite 2025, a major upgrade to its suite of...

ADINA 2025 for Structural WorkSuite

May, 13, 2025 | NewsThe Structural WorkSuite provides access to the RAM and STAAD structural analysis products and now...

How advanced finite element analysis can prepare buildings for extreme events

Nov, 14, 2024 | NewsWhile most structural analysis software can evaluate everyday stresses, they often fail to prepare...

Bentley Systems Announces Acquisition of ADINA to Extend Nonlinear Simulation throughout Infrastructure Engineering

May, 05, 2022 | NewsBentley Systems announced it has acquired Watertown, Massachusettsbased ADINA R & D Inc., a lea...

Form

Looking for more information? Fill in the form and we will contact Bentley for you.

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Architects design for medicine…

Maine Medical Center

Spectacular interchanges around the world

World’s longest single-tower bridge nears completion