Structural Engineering meeting Nature: Western Australia’s Kalbarri Skywalks

Using innovative structural engineering design solutions and being blended into the natural environment, the Kalbarri Skywalks in Western Australia opened to the public in June 2020. The steel cantilevered structures extend over the Murchison River Gorge in Kalbarri National Park, Western Australia. With a clear overhang of 25 m, the cantilever of Skywalk 1 is approximately 4 m longer than the Grand Canyon Skywalk.

The structural engineering design was carried out by Terpkos Engineering, and the project team won a 2020 Australian Engineering Excellence Award. Terpkos Engineering Director Paul Terpkos explained to Engineers Australia that “the skywalk decking is largely constructed from fibre reinforced polymer (FRP) mesh flooring and rectangular hollow section joists. [] The FRP was selected due to its low maintenance requirements and long term design life. A glass surface requires relatively high ongoing maintenance or would typically require full time supervision.”

credits: Department of Biodiversity, Conservation and Attractions

Andrew Jens, the senior structural engineer on the project, further described the design details to Engineers Australia. “The connection between the weathering steel box beam and the cast in sleeve plate at the end of the concrete beam required 27 M36 bolts to the top and bottom, and 30 M24 bolts to each side plate. The minimum tension in the M36 bolts to induce the required friction between the plates is 490kN per bolt. Rock anchors were used at the rear concrete beam footings to restrain the footing from uplift, the rock anchors extend 10 metres below the underside of footings.”

Jens added that a key aspect of the project was the minimization of the maintenance requirements over the 100-year design life. “The weathering steel is high strength, with a yield strength of 340 MPa, and the unique chemical composition forms a protective layer of patina that reduces the material loss due to corrosion. The use of weathering steel had implications for the detailing of the structure, it is critical to ensure that water can effectively drain from the structure” Jens stated.

Finally, the structural engineers had to consider the dynamic response of the structure, with a goal being the minimization of vibrations cause by crowd movement. Andrew Jens said that “after some modifications to the box spine beams to maximise the natural frequency, the maximum acceleration was found to comply with AS 5100 Bridge Structures for the critical footfall frequency.”Sources: ENGINEERS AUSTRALIA, Department of Biodiversity, Conservation and Attractions

Want to read more like this story?

Structural Analysis

Sep, 16, 2022 | EducationThe prediction of the response of structures when they are subjected to specified arbitrary extern...

Bentley Webinar | Advanced Design & Analysis of Industrial & Commercial Structures

Jul, 20, 2023 | EventElevate Your Concrete and Steel Design: Embrace the Power of RAM Connection and STAAD Advanced Conc...

Bentley Webinar Series: Transforming Engineering with Bentley's Advanced Structural Solutions

Aug, 12, 2024 | EventJoin this unique Bentley webinar series to explore STAAD.Pro, Structural Worksuite and RAM Connecti...

Structural Engineering Libary

Nov, 04, 2016 | SoftwareBeams

Sep, 14, 2023 | EducationBeam, in structural engineering, is a horizontal structural element that is designed to carry and...

Structural Engineering Finalists in the 2023 Going Digital Awards in Infrastructure

Sep, 01, 2023 | NewsThe annual awards program honors the extraordinary work of Bentley software users advancing infrast...

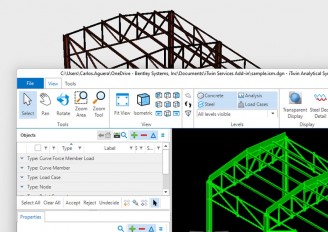

Designing Steel Connections from Your Structural Analysis Program

Apr, 07, 2022 | NewsIf beams and columns are the bones of a structure, then connections are the joints that keep it all...

Bentley Webinar: Achieving Enhanced Structural Detailing and Connection Design for Industrial Structures

Jun, 10, 2025 | EventStructural engineers often need solutions for analyzing industrial structures, detailing, and conne...

Steel Structures

Jan, 01, 2019 | EducationThe term “steel structures” refers to constructions that rely primarily on steel as the main build...

Trending

Spectacular interchanges around the world

New Release - STAAD.Pro 2024 - 2

ADINA 2025 for Structural WorkSuite

ADINA 2025 New Release!

Concrete Buildings as Rechargeable Batteries

Powerful earthquake shakes central Philippines, dozens killed