EPFL scientists develop hydrogel-based 3D printing that yields metals 20× stronger

Researchers at the École Polytechnique Fédérale de Lausanne(EPFL) have developed an innovative additive manufacturing method that begins with hydrogels rather than metal-infused resins. The team’s approach allows them to infuse a printed gel framework with metal salts, convert them into dense nanoparticles, and ultimately produce metals and ceramics that reportedly withstand 20 times more pressure than structures made by conventional 3D printing.

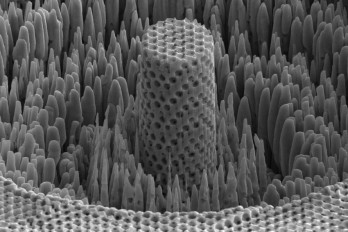

Their technique works as follows: first, a water-based gel scaffold is 3D printed. This “blank” gel structure is then soaked repeatedly in metal salt solutions, triggering a chemical conversion that deposits metal nanoparticles throughout the gel network. Through multiple cycles, typically 5 to 10 infusions ,the metal concentration increases until the scaffold is saturated. Finally, the gel is removed by heating, leaving behind a dense metallic or ceramic structure that mirrors the original shape. (Source)

This method addresses two major issues that hamper conventional metal additive manufacturing: porosity and excessive shrinkage. Past techniques often produce parts with internal voids and significant dimensional changes due to material contraction, weakening both geometry and mechanical performance. In contrast, the EPFL approach yields parts that are much denser and more stable.

Tests on gyroid lattice structures made from iron, copper, and silver showed dramatic improvements. The new components sustained 20 times the pressure of prior equivalents while exhibiting only about 20 % shrinkage, compared to 60–90 % shrinkage typical in older methods.

The flexibility of the process is another notable advantage. Because the hydrogel template is agnostic to material—being just a carrier structure—the same printed scaffold can produce parts in different metals, ceramics, or composite forms, depending on which salts are used in infusion.

EPFL researchers envision applications in fields requiring lightweight, high-strength, complex geometries, such as energy systems, sensors, biomedical devices, or porous catalysts. The control over geometry plus improved material strength may unlock new possibilities in these domains.

One caveat: the multi-cycle infusion process is relatively time-intensive compared to direct metal printing techniques. The research team is exploring automation and robotics to speed up processing and make the method more suitable for industrial scale.

This development represents a paradigm shift in additive manufacturing: instead of embedding material choices at the printing stage, material composition becomes a post-printing decision, a reversal of conventional flow in 3D printing.

Sources: Scitech Daily, EPFL

Want to read more like this story?

Metal structures

Sep, 07, 2023 | EducationMetal structures refer to constructions primarily built using metal as the fundamental building ma...

ETH Zurich: Introducing a new robotic method in 3D-printing field as a more sustainable alternative

Nov, 07, 2024 | NewsETH Zurich researchers introduced a revolutionary 3D-printing technique that is known as Impact Pri...

The world’s most exceptional 3D printed homes

Apr, 10, 2024 | News3D printing technology is a revolution at the construction sector, enabling builders to fabricate h...

Dubai plans to build the world's first 3D-printed mosque

May, 03, 2023 | NewsDubai aspires to build the world's first 3D-printed mosque, that will cover an area of 2,000 square...

A 29-meter-long 3D printed bridge is under construction in the Netherlands

Apr, 05, 2021 | NewsThe world's longest 3D printed pedestrian concrete bridge is currently under construction in the...

New solution promises 90% cost reduction in concrete 3D printing materials

Dec, 22, 2021 | NewsConcrete 3D printing of building shells has grown considerably in the last few years, with more and...

Printout homes using new techniques: the rise of 3D-printed houses

Aug, 18, 2021 | NewsPalari Homes and Mighty Buildings company is using a new technique to build houses within 24 hours....

New lightweight material has the strength of titanium

Feb, 22, 2019 | NewsResearchers have developed a sheet of nickel with nanoscale pores that has the strength of titanium...

First 3D-printed building in Dubai

Jul, 29, 2019 | NewsThe first building realized via 3D printing technology in Dubai will be developed by Emaar Prop...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Spectacular interchanges around the world

Maine Medical Center

Buildings Prone to Earthquakes

Roof collapse at Curragh Coal Mine leaves one worker missing