Can wood compete with steel and concrete as a building material?

Wood presents a lot of benefits as a building material because it is strong, lightweight and environmental friendly. However, only changes in building codes will make wood competitive with steel and concrete.

Wood is in fact the oldest construction material, common in almost every continent and culture. However, the use of wood in construction until recently was very rare. In large parts of the world wood has been replaced by bricks, steel and concrete. The largest contributor to the abandonment of the wood was the fear of fire so it was replaced by non-combustible materials despite the fact that some of them, although non-flammable, may ironically perform worse in cases of fire (for example, steel usually fails faster than wood and can expand, triggering faster collapse), a fact that has been largely ignored by the construction industry, building owners and regulators.

In the past 2 decades we witnessed a revival of wood as a construction material. Buildings with great significance were built with wood. These include:

- The Stadthaus in London, UK (8 floors)

- The Forte in Melbourne, Australia (10 floors, of which 9 are built with wood)

- The Wood Innovation and Design Center in Prince George, Canada (7 floors)

- The Treet in Bergen, Norway (14 floors)

- The Brock Commons in Vancouver, Canada (18 floors, of which 17 are built with wood).

As a material, it is lightweight with a high strength-to-weight ratio. Comparing wood and steel beams with similar geometry and weight, the wooden beams will most likely outperform the steel beams in terms of load capacity. This realization is certainly not new. It is a property that in the past has seen ships, cars and planes fabricated with wood.

In seismic zones, the flexibility of wood and the ductility of some connection details, combined with its lower weight, make wood an attractive alternative to steel and concrete. Moreover, wood is perfectly suited for use in prefabrication and the production of wood panels can be optimized in terms of accuracy and efficiency, saving time and money.

Yet, the most important advantage of wood is that it naturally reduces the construction energy and helps to reduce the overall impact of a building. It is a renewable resource, has a lower embodied energy (the total energy used in the processes associated with the construction of a building) than steel and concrete, and it can even sequester carbon, possibly resulting in a positive contribution to the building's carbon footprint. Therefore, if the building code requires better-performing buildings with a lower environmental impact, the construction industry will need to deliver thicker and better-insulated envelope components. This has already led to fundamental changes in the construction industry in numerous parts of the world, and is a process that is still ongoing in areas where the code is currently less demanding in terms of thermal and environmental requirements. If this is the direction where the regulations are heading, wood construction industry will be in the position to meaningfully compete with steel or concrete, not only from an environmental point of view, but also in terms of quality and cost.

Source: Nature.com

Want to read more like this story?

Wood in construction: efficiency and saving

Aug, 25, 2016 | NewsAlthough concrete and steel are the most commonly used building materials, a structure made of wood...

Metsa Wood and the Plan B

Jul, 10, 2015 | NewsMetsa Wood, a Finnish quality wood products producer, has developed a "Plan B" campaign, which aims...

Wood Structures

Sep, 07, 2023 | EducationWood structures are constructions primarily built using wood as the main structural material. They...

World's Tallest Wooden Structure to be Built Next Year

Mar, 11, 2015 | NewsAt 270-feet and €60M plans for the world’s tallest wooden structure, to be built next year, have bee...

A material to protect constructions from natural disasters

Dec, 13, 2018 | NewsA new 3D cementitious panel is introduced as a material that could protect houses from natural disas...

WinWood

Dec, 02, 2013 | Software

Steel or Timber? Carbon footprint of truss structures can be reduced with the aid of new studies

Nov, 29, 2021 | NewsBuildings contribute significantly to global warming, not just in their ongoing operations but in t...

Sustainable materials can be used in construction to decrease environmental pollution

Apr, 30, 2024 | NewsEfforts to reduce emissions in the building sector typically focus on operational aspects like heat...

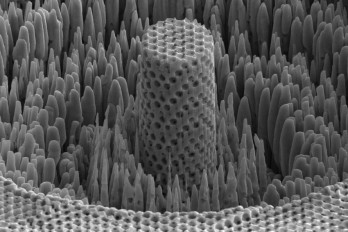

New lightweight material has the strength of titanium

Feb, 22, 2019 | NewsResearchers have developed a sheet of nickel with nanoscale pores that has the strength of titanium...

Trending

New Release - STAAD.Pro 2025

Melbourne Approves Skinny Skyscraper

Spectacular interchanges around the world

Maine Medical Center

Buildings Prone to Earthquakes

Roof collapse at Curragh Coal Mine leaves one worker missing