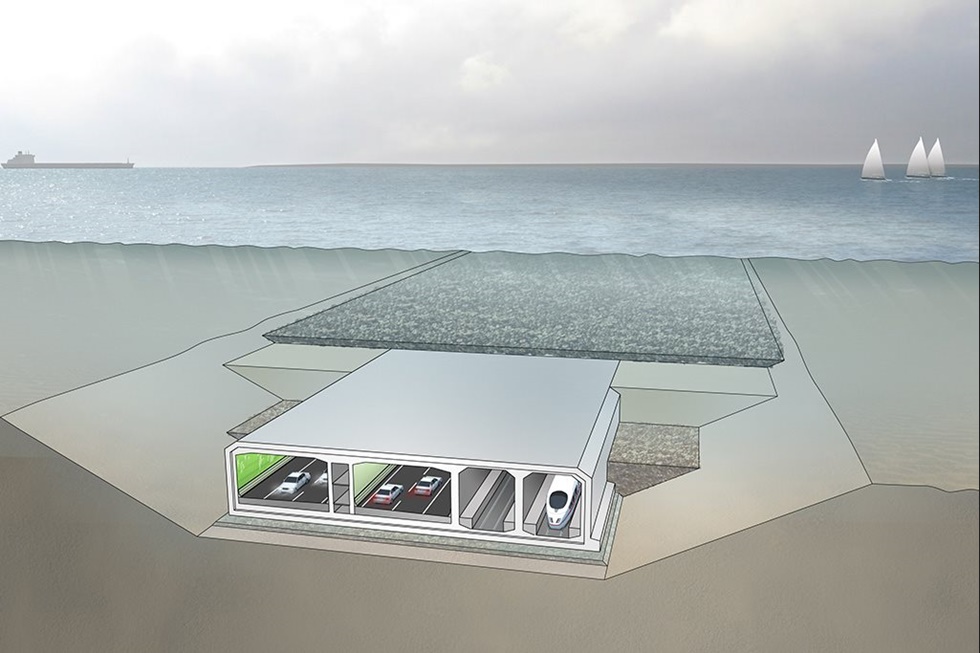

World’s longest immersed road and rail tunnel also features remarkable design solutions

The Fehmarnbelt fixed link in the Baltic Sea will connect the Danish island of Lolland with Germany's Fehmarn island and is expected to boost transportation between central Europe and Scandinavia. Spanning 17.6 km, it will be by far the world’s longest road and rail immersed tube tunnel (IMT), comprising of a four-lane motorway and a double-track railway. The Fehmarnbelt link will cut journeys across the sea from 45 minutes to about 10 by car and 7 by train.

The tunnel has been approved for construction in Denmark since April 2015, but due to the complicated approval process in Germany, the construction process is just about to begin. Its planning and construction is being undertaken by the state-owned Danish company Femern A/S , with a Ramboll / Arup / TEC joint venture serving as the main consultant for the company since 2009, while the cost is estimated at around €4bn.

Extraordinary dimensions

Apart from its record-breaking length (it is more than 5 times longer than the tunnel under the Øresund strait linking Denmark and Sweden), the Fehmarnbelt crossing will also have an impressive width of 42 m! When completed in 2028, it will be one of the deepest tunnels of this type too, as its foundation depths reach more than 40 m below sea level.

Special elements and characteristics

The need to minimize the tunnel’s cross-section, while accommodating the necessary mechanical and electrical systems essential for the tunnel’s operations, led Ramboll company to the solution of installing a total of 10 double-decked ‘special elements’ positioned about every 1.8 km. Each of these elements is 39 m long, 45 m wide, 13 m high and contains an upper road / rail deck level with an installations level beneath. They will also provide other benefits, such as parking access for maintenance vehicles and access to mechanical and electrical equipment without interfering with traffic.

More than 3 million m3 of concrete will be required for the construction of the tunnel, together with the placement of 360,000 tons of reinforcement. In order to make logistics easier, a large harbor will be constructed to house the several batching plants that will provide this massive concrete production and also ensure that cement and aggregates will be available in sufficient quantities.

The way the tunnel will be ventilated is also innovative, as it is designed as a longitudinal system where the need for costly intermediate ventilation shafts has been eliminated. Using sophisticated ventilation modelling and taking into account the growth of traffic in relation to a reduction in car emissions as vehicle technology improves, the ventilation system is expected to keep conditions at globally recognized levels during the whole lifetime of the tunnel.

Source: Construction News

Media

Want to read more like this story?

Fehmarn Belt will be Longest Tunnel in the World

Apr, 24, 2015 | NewsSlated at $10 billion, construction on the Fehmarn Belt Fixed Link could start as early as this year...

The proposed LA tunnel system by Elon Musk’s Boring Company has been revealed

Dec, 19, 2017 | NewsElon Musk, frustrated by LA’s heavy traffic, has proposed to create tunnels for an underground trans...

Video: In 2016 the new undersea road tunnel in Istanbul

Oct, 09, 2015 | NewsAn ultra-modern underwater road tunnel in Istanbul is taking place and it will be launched in late 2...

The Longest Underwater Tunnel

Jul, 13, 2015 | NewsThe underwater tunnel is a huge project with a cost at around 36 billion US dollars, with a length t...

The Longest Train Tunnel Has Been Completed

Sep, 02, 2015 | NewsIt is a fact that the 38-mile train tunnel that links Switzerland and Italy has finally been complet...

A unique in-tunnel grouting project by Keller at Merbourne's Metro Tunnel

Jun, 08, 2021 | NewsAfter months of careful design planning and on-site expertise, Keller has successfully completed a...

The construction of the longest single-headed undersea high-speed railway shield tunnel completed in South China after 33 months

Mar, 15, 2024 | NewsAn innovative achievement was reached in South China on Friday 15th of March with the completion of...

A drone flight inside Seattle’s SR99 tunnel

Nov, 13, 2017 | NewsIt was April 4, 2017, when the work of tunneling machine Bertha was complete, breaking thr...

The world's longest sea bridge will also be ‘green’, featuring electric vehicle charging stations

Sep, 01, 2017 | NewsThe first major combined bridge and tunnel sea-crossing project in China is the Hong Kong-Zhuhai-Mac...

Trending

Spectacular interchanges around the world

Eshima Ohashi bridge in Japan designed for the brave!

Building partially collapses in Philippines: 2 people injured

Concrete Component Design Using STAAD.Pro

Potential problems and solutions in steel structures